Fabrican’s Spray-on fabric and coating technology is heralding the twenty-first century era of mass customisation. Multinational manufacturers in the healthcare, automotive, and consumer product industries are implementing use of Fabrican’s innovative technology in their production facilities.

The flexibility of Fabrican’s technology offers a groundbreaking mass customisation manufacturing process, like 3D printing for fabrics. The versatility of a sprayable fabric coating that seamlessly conforms to any shape removes technical and economic barriers to producing innovative and personalised products. Fabrican’s spray technology enables producers to readily vary products’ physical properties (shape, size, texture, or colour) to suit each customer’s specification, without the need for re-tooling or stocking different grades of material.

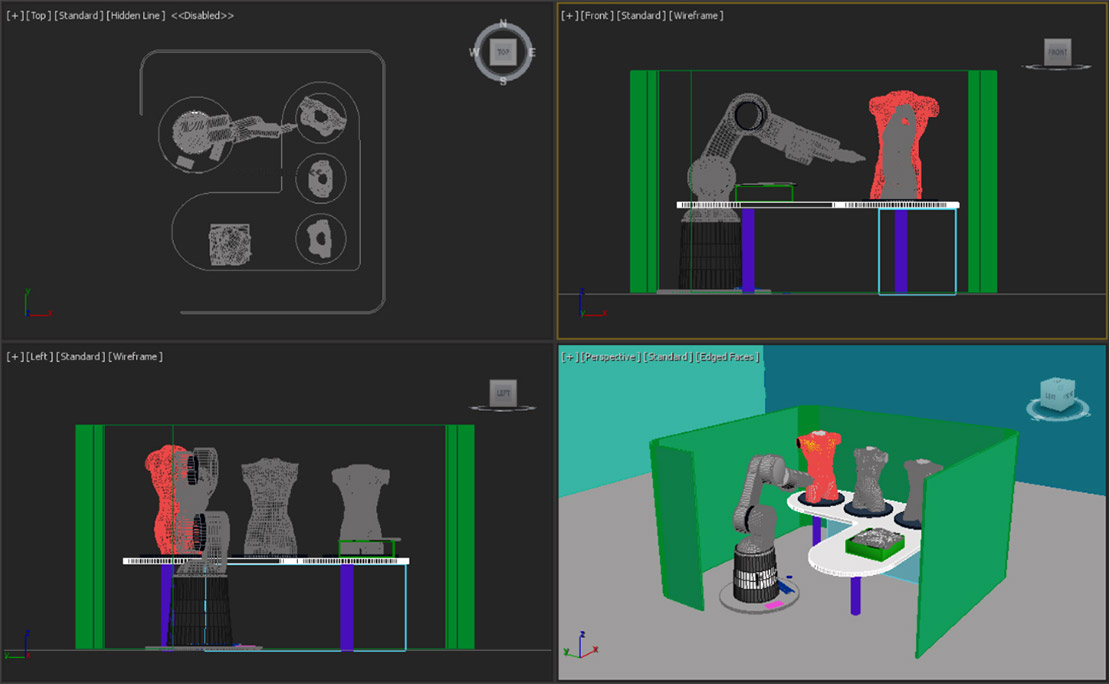

A single robotic sprayer and PLC (programme logic controller) can be a multi-purpose tool, creating multiple products with different characteristics by adjusting liquid fibre solution and/or reprogramming. The reduction in capital costs, realised by replacing many machines with one robotic sprayer, offers enhanced accessibility for starting businesses, and for producers in less developed countries.

Sprayable fabric technology means that many currently manual processes can be automated, saving manufacturers labour costs—at the same time as reducing reliance on overseas component suppliers. It further reduces cost by compressing the industrial supply chain (fewer manufacturing steps, fewer intermediaries, much faster process) and eliminating excess inventory and warehousing requirements, as non-woven materials can be created on-demand, on-site.

Spray-on fabric technology offers significant environmental benefits. Closed loop manufacturing processes can recycle up to 99% of solvents by a solvent recovery system. This sustainable solution offers maximum value, reduces environmental impact and contributes to the circular economy by reprocessing solvents to manufacture greener products that can be reused again and again. The fabric products themselves can be recycled after use again and again, while increased local production and reduced reliance on overseas-sourced materials will reduce carbon emissions from heavily polluting container shipping.

Fabrican’s spray-on fabric technology applies instant, non-woven fabrics to car interior surfaces where lightweight, durable, and stain-resistant fabrics are required. Under the hood and within the engineering, Fabrican can isolate and protect components and secure wiring with heat-resistant lightweight coatings applied by spray.

Automotive

Fabrican’s unique spray-on application method liberates car interior designers from the constraints of conventional forms; paired with robotic sprayers, Fabrican can create multi-purpose fabrics and coatings with different characteristics by adjusting liquid components and/or reprogramming. The technology offers automotive manufacturers significant efficiency benefits with fewer manufacturing stages, a much quicker process, and a reduction in labour costs.

For fleet operators and private motorists, applications include upholstery or interior renovation and repairs to give a fresh new look to the vehicle.

- Car interior, dashboards, seats, door panels, headliner.

- Customisation or adaptation by trade professionals or private individuals.

Robot arm spray system, Fabrican 2020

Fabrican’s technology in combination with robotic sprayers has the potential to transform manufacturing. Robotics offer the ability to spray materials swiftly, precisely and consistently. Capable of spraying 9m of material per second, robotic arms can rapidly create seamless complex shapes or whole garments. Operating 24 hours a day, seamless robotic spray manufacture offers significant cost benefits in terms of labour and component costs.